WE PRODUCE OVER 800,000 COMPONENTS PER MONTH

WE GUARANTEE HIGH QUALITY STANDARDS AND HIGHEST PRECISION

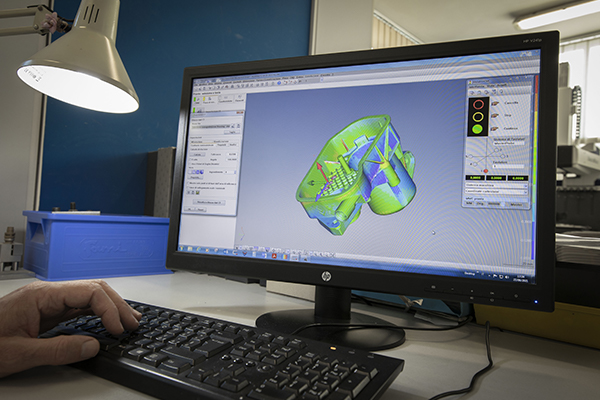

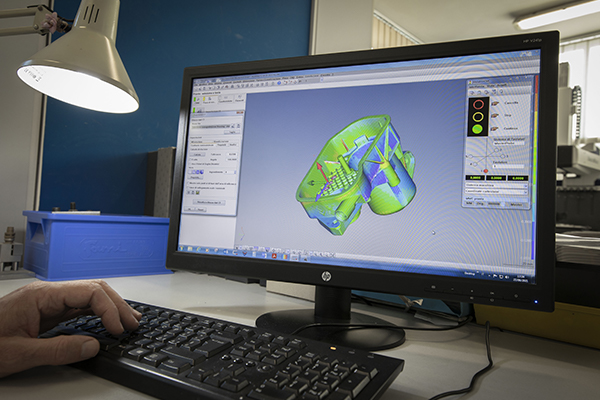

DESIGN AND CO-DESIGN

During the development stage we provide the necessary advice and support to our customers, by checking that the technical characteristics of the components are adequate and by making changes to optimize production and quality of what is molded if it is necessary.

We start from your ideas, to bring your projects to life. A team work carried out together to obtain a result that guarantees functionality and durability of the proposed solutions.

COMPONENTS PROTOTYPING

We can develop prototypes of equipment and components to check their correct performance and operation.

A prototype is the ideal solution when there is a need to physically test the functionality of the technical solutions used and anticipate any future critical issues.

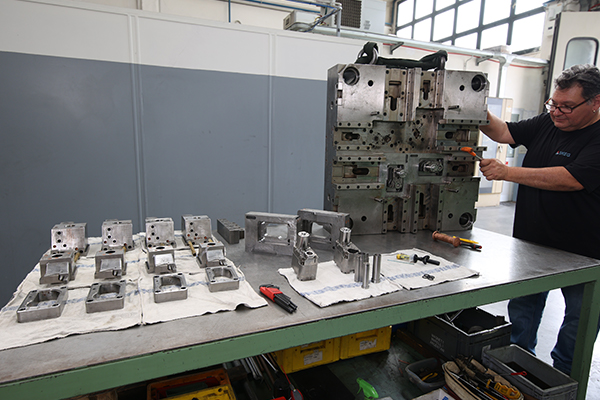

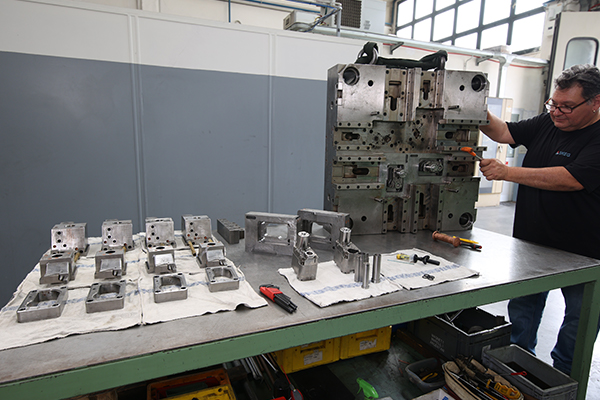

MOULD CONSTRUCTION

Upon request, we can take care of the mould construction and the necessary equipment for the individual components.

A direct connection between the mould making workshop and the moulding department is the best guarantee of compliance with the timing and requirements of each project.

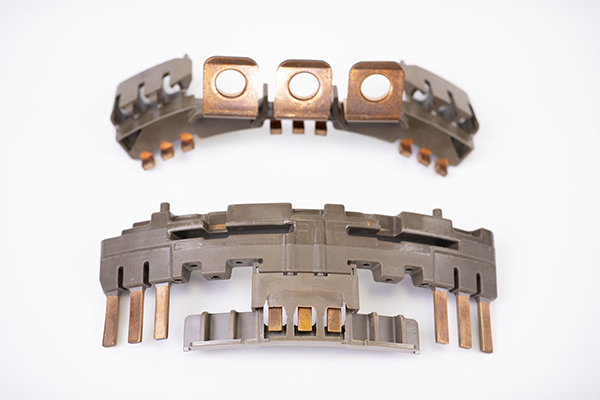

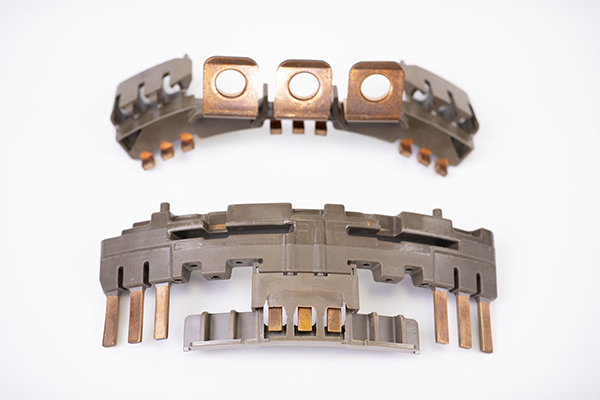

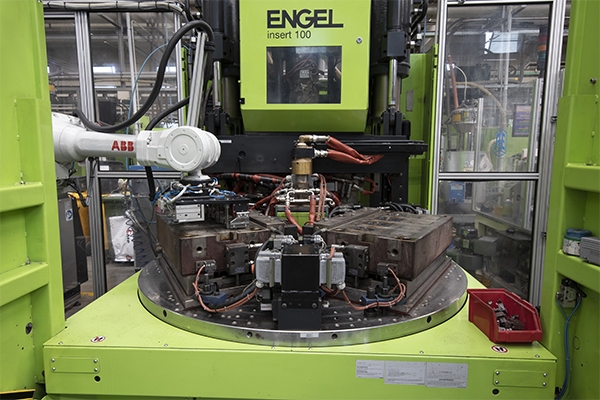

STAMPING AND MOLDING

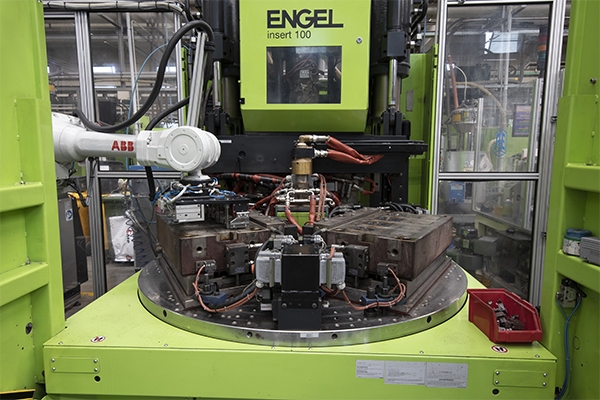

A fleet of over 30 presses, from 50 to 400 tons, which has grown over the years thanks to constant investments and an entrepreneurial vision of the future.

The moulding departments are equipped with Engel horizontal presses, fitted with automatic plastic material loading systems.

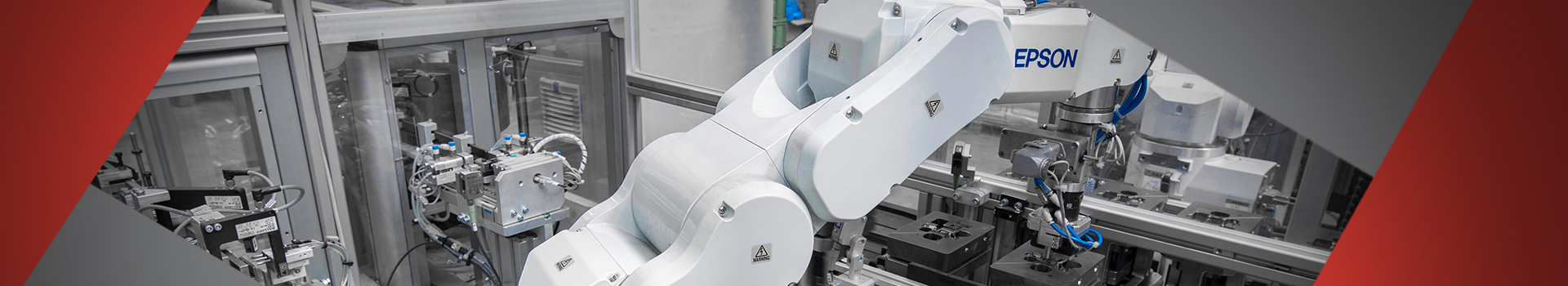

Our robotized co-moulding lines are the best technological solution to guarantee high quality and high production output.

We can process numerous plastic materials, such as:

PEEK, PA, PEI, PPS, PBT, LCP, PET, TVP.

COMPONENTS ASSEMBLY

We design and build the equipment necessary for assembling and processing plastic components.

Our experience and our technical knowledge allow us to establish with our customers a relationship of complete trust and reliability

RAW MATERIALS WAREHOUSE AND FINISHED GOODS STORAGE

We stock up plastic polymers of certified quality from the world’s leading manufacturers. We want to ensure to our customers value, specificity, and maximum reliability in every aspect and use.

DESIGN AND CO-DESIGN

During the development stage we provide the necessary advice and support to our customers, by checking that the technical characteristics of the components are adequate and by making changes to optimize production and quality of what is molded if it is necessary.

We start from your ideas, to bring your projects to life. A team work carried out together to obtain a result that guarantees functionality and durability of the proposed solutions.

COMPONENTS PROTOTYPING

We can develop prototypes of equipment and components to check their correct performance and operation.

A prototype is the ideal solution when there is a need to physically test the functionality of the technical solutions used and anticipate any future critical issues.

MOULD CONSTRUCTION

Upon request, we can take care of the mould construction and the necessary equipment for the individual components.

A direct connection between the mould making workshop and the moulding department is the best guarantee of compliance with the timing and requirements of each project.

STAMPING AND MOLDING

A fleet of over 30 presses, from 50 to 400 tons, which has grown over the years thanks to constant investments and an entrepreneurial vision of the future.

The moulding departments are equipped with Engel horizontal presses, fitted with automatic plastic material loading systems.

Our robotized co-moulding lines are the best technological solution to guarantee high quality and high production output.

We can process numerous plastic materials, such as:

PEEK, PA, PEI, PPS, PBT, LCP, PET, TVP.

COMPONENTS ASSEMBLY

We design and build the equipment necessary for assembling and processing plastic components.

Our experience and our technical knowledge allow us to establish with our customers a relationship of complete trust and reliability

RAW MATERIALS WAREHOUSE AND FINISHED GOODS STORAGE

We stock up plastic polymers of certified quality from the world’s leading manufacturers. We want to ensure to our customers value, specificity, and maximum reliability in every aspect and use.